Deciphering Water Pipe Relining Methods

Deciphering Water Pipe Relining Methods

Blog Article

In this article in the next paragraph you can find a good deal of dependable guidance pertaining to Relining Sewer Drain Pipes.

Intro

Repairing damaged water pipes does not require excavating deep into your sewer lines and trying to replace them anymore. Well, Pipeline Relining, of course.

What is Pipeline Relining

Pipe Relining is a means of repairing broken water pipes without digging. While Pipe Relining is a terrific approach for pipe repair, only a professional plumber can recommend this damages fixing method.

The secret to reliable Pipe Relining is producing a more powerful pipeline by infusing resin in the damaged pipeline utilizing a resin really felt tube. Forming a more powerful pipeline is just possible when the resin cures, lasting a very long time.

5 Benefits of Pipe Relining

Pipe relining is unarguably a better option compared to the traditional digging method. It comes with some benefits, which makes it a better choice for all pipeline repair service conditions. These are some of the advantages of pipeline relining;

The expense of pipe relining is fairly low. Considering that no concrete infiltration or trench excavating is called for, you don't have to bear the cost of durable equipment, replenishing trenches, as well as cleaning up the work area.

Relining takes little time to be finished. No extra manpower is required as well as the entire procedure is simple and easy, particularly when it is being done by an expert plumbing solution. Dealing with inaccessible locations is also simpler utilizing this technique.

The material provides an additional coating for your weak pipes, leaving you with a two-in-plumbing unit. The epoxy resin often tends to be more powerful than the initially installed pipeline.

Unlike the traditional trench digging procedure, the possibilities of crashes caused by an interfered with floor surface are drastically reduced. Passengers can move easily without disrupting the fixing procedure and vice versa.

The epoxy lining has a smooth surface area and also is without obstructions that decrease the circulation of water. After relining your water pipes, be anticipating a much better and smoother water circulation.

Just How is Pipeline Relining done?

Prompt pipe repair work is necessary in minimizing the strength of the damages. The good news is you can get your pipes taken care of in the area of 1 day by just connecting to our emergency plumbing solutions. The whole procedure fasts and not as onerous as the conventional fixing process.

Right here is a step by step procedure in relining of pipes;

Carefully observing the level of pipe damage is the initial step in pipeline relining. The Forced Electron Leak Area tools is used to very closely assess your plumbing system for blockages and also damages. By doing this, developing a remedy is possible.

The pipeline is cleaned and all blockages eliminated to allow for very easy water flow. Later, the pipe wall surfaces are gotten ready for resin application using a high-pressure water jet.

The size of your pipes is then loaded with epoxy resin, which develops the more powerful pipe after treating. This action gets harder when handling T-sections.

Curing can be done in two ways; leaving it to heal manually or accelerating the process by using warm water. Either method works - it simply relies on just how quickly you desire the lining cured.

Junctions are gotten rid of conveniently using robot cutters. Nevertheless, inspection pits can only be cut utilizing surface-level cutters or grinders.

Final assessment

Our pipe relining services guarantees that all relined pipes are fully inspected making use of a drainpipe evaluation electronic camera. The final examination includes testing to see if relined pipelines are completely sealed.

Final Judgment

You can never ever fail with pipeline relining. Conserving all that money and also energy spent on digging trenches certain really feels good. Do not hesitate to contact our specialist pipe relining service that maintains your whole plumbing system in the very best condition possible.

Bear in mind, acting quickly is the only way to decrease the impact of your pipe damage. More damages means even more cost to incur.

Pipeline Relining is a method of repairing damaged water pipes without excavating. The CIPP method includes fixing a pipeline from the within by utilizing a special material, which treatments over time, producing an even stronger pipeline throughout its procedure. While Pipe Relining is a wonderful approach for pipeline fixing, just a professional plumber can recommend this damage repair approach.

Pipe relining is unarguably a better alternative compared to the conventional excavating method. Closely observing the extent of pipe damage is the very first step in pipeline relining.|

Introduction

Repairing busted water pipes does not need excavating deep right into your drain lines as well as trying to change them anymore. Well, Pipe Relining, of program.

5 Advantages of Pipeline Relining

Pipeline relining is unarguably a better alternative contrasted to the typical excavating technique. It includes some benefits, that makes it a more suitable option for all pipe fixing conditions. These are several of the advantages of pipeline relining;

The price of pipe relining is fairly reduced. Given that no concrete penetration or trench digging is needed, you do not need to pay of heavy-duty equipment, re-filling trenches, and cleaning the workspace.

Relining takes little time to be completed. No extra manpower is required and the whole procedure is uncomplicated, particularly when it is being done by an expert plumbing solution. Managing unattainable locations is additionally easier using this approach.

The material offers an extra coating for your weak pipelines, leaving you with a two-in-plumbing unit. The epoxy material often tends to be stronger than the at first set up pipe.

Unlike the standard trench excavating procedure, the possibilities of mishaps triggered by an interrupted flooring surface area are significantly decreased. Residents can relocate openly without disrupting the fixing procedure and vice versa.

The epoxy lining has a smooth surface area and is devoid of blockages that decrease the circulation of water. After relining your pipes, be expecting a much better and also smoother water flow.

How is Pipeline Relining done?

Prompt pipeline repair service is crucial in lowering the intensity of the damage. The good news is you can obtain your pipelines taken care of in the space of 24 hours by just reaching out to our emergency plumbing solutions. The entire process fasts and also not as burdensome as the standard repair work procedure.

Here is a step by step procedure in relining of pipes;

Very closely observing the level of pipe damage is the initial step in pipe relining. The Forced Electron Drip Place devices is used to closely examine your plumbing system for blockages and damages. In this manner, creating a remedy is possible.

The length of your pipes is after that filled with epoxy material, which develops the more powerful pipe after healing. When dealing with T-sections, this step gets harder.

The pipe is cleaned and all clogs eliminated to permit very easy water circulation. Later, the pipe walls are prepared for resin application using a high-pressure water jet.

Treating can be done in two methods; leaving it to treat manually or increasing the procedure by using hot water. Either method works - it just depends on how promptly you want the lining treated.

Our pipeline relining solutions makes sure that all relined pipelines are fully inspected utilizing a drain assessment electronic camera. The last inspection includes testing to see if relined pipelines are entirely sealed.

Junctions are gotten rid of easily utilizing robotic cutters. Nevertheless, evaluation pits can just be cut making use of surface-level cutters or mills.

What is Pipe Relining

Pipe Relining is a method of fixing broken water pipelines without excavating. While Pipe Relining is a wonderful technique for pipeline repair, only an expert plumber can recommend this damage repair service method.

The trick to effective Pipeline Relining is producing a stronger pipeline by infusing material in the harmed pipeline using a material really felt tube. Forming a more powerful pipeline is only feasible when the resin treatments, lasting for a long time.

Last Decision

You can never ever go wrong with pipe relining. Saving all that cash as well as energy spent on excavating trenches certain really feels great. Do not wait to call our expert pipe relining solution that maintains your entire plumbing system in the very best problem feasible.

Bear in mind, acting rapidly is the only means to decrease the result of your pipe damages. Even more damages means even more expense to sustain.

Pipe relining is unarguably a far better choice compared to the typical digging method. Very closely observing the level of pipe damages is the first action in pipeline relining. Pipeline Relining is a means of repairing damaged water pipelines without excavating. The CIPP technique entails repairing a pipeline from the within by utilizing an unique material, which cures over time, creating an even more powerful pipe throughout its procedure. While Pipeline Relining is a wonderful technique for pipe repair, only an expert plumber can advise this damage repair work method.}

WHAT IS PIPE RELINING, AND HOW DOES IT WORK?

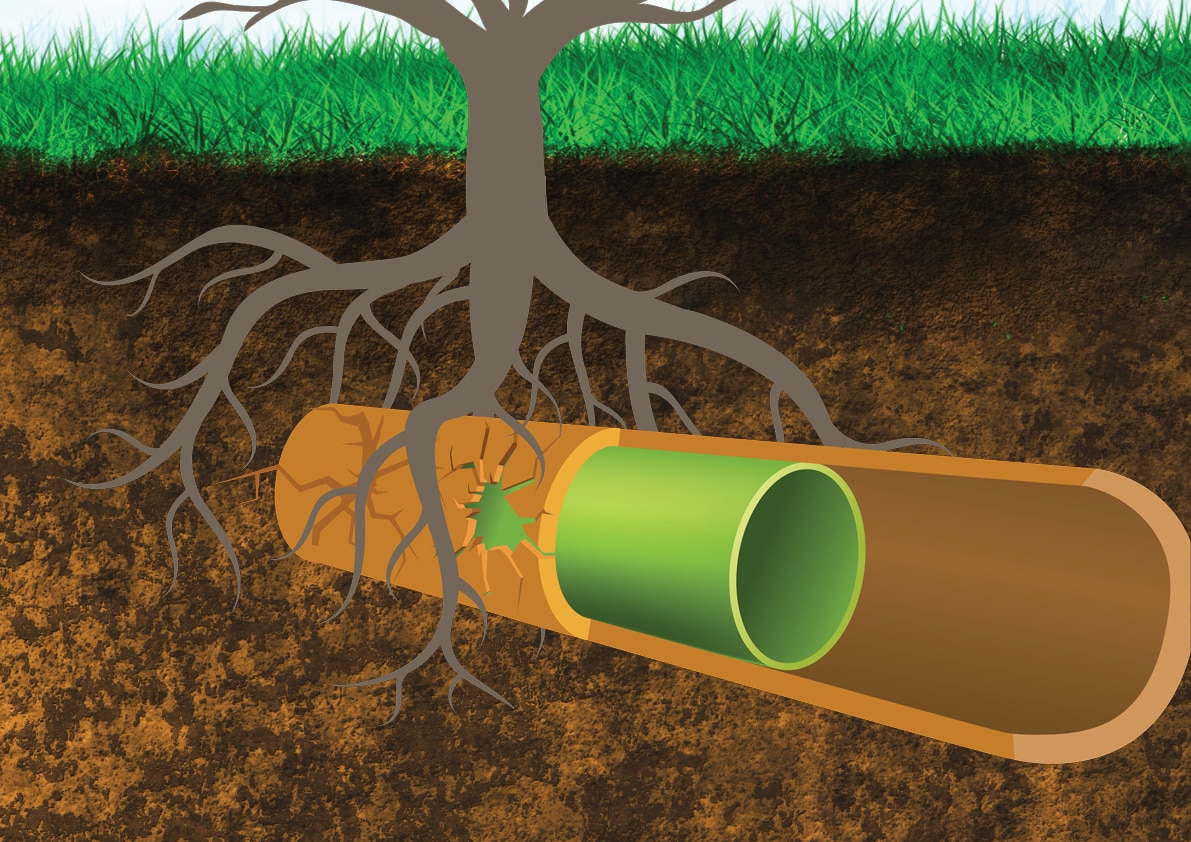

We’re often asked how it’s possible to repair broken pipes without digging them up to patch them or replace them. Pipe relining is a no dig pipe repair method that was created to solve exactly this problem! This has made pipe relining more and more popular with home owners who aren’t keen on destroying their yard or knocking down any walls.

SO, WHAT IS PIPE RELINING?

Pipe relining is a way of repairing cracked or broken pipes from the inside, without digging. Essentially, it means creating a new, tough pipe inside the existing damaged one, promoting a better flow and sealing off cracks. The section that is relined seals perfectly against the rest of your pipe system, stopping leaks and preventing further breaks.

At Nuflow, our relined pipes are even stronger than brand new pipes, and because there’s no excavation required, you won’t need to mess up your garden like you would if you were replacing your pipes entirely.

HOW DOES IT WORK?

From one pipe relining supplier to the next, there are some different methods and approaches to relining pipes. At Nuflow, we use a cured in place pipe relining method to reline and repair broken pipes and blocked sewers.

With our custom-made composite resin solution, we create a new pipe inside your existing broken pipe. Our patented methodology has been honed over the last few decades by our in-house polymer engineers, industrial chemists, and research and development team.

Check out our process for relining pipes.

We inspect and measure the pipes

First, we send the drain camera down to assess the plumbing system to find any breaks and pipe blockages, and measure up. This helps us work out exactly what the problem is and where it’s situated.

Our certified technicians create a custom pipe lining and bladder

Once we have the measurements, we create a custom felt liner, and an inflatable bladder to match the exact specifications of the pipe, including any bends or junctions.

We install the pipe relining solution

When we’re ready to install the relined section of pipe, we soak the felt liner in an epoxy resin, and insert the uninflated bladder into the pipe liner. A rope is attached to each end of the liner, which we use to pull the pipe liner into place by using the existing access points to your pipes.

By using the attached ropes and the existing access points to your pipes, we pull the felt liner and uninflated bladder into place inside the pipe, without any digging. We line it up by using a specialist drain camera to make sure it’s in exactly the right spot. Then, we inflate the bladder with air, which blows out the felt liner to seal against the existing pipes, creating a new pipe that holes up any breaks or cracks. The bladder remains inflated until the resin has cured to create a hard, tough pipe.

Then we deflate the bladder and pull it back out of the pipe, leaving you with a brand new, tough and watertight pipe.

The relined section is checked and tested

Once your pipe has been relined, we use our CCTV drain inspection camera to check that everything has been installed and sealed correctly.

https://nuflow.net/what-is-pipe-relining-and-how-does-it-work/

Do you like reading up on Pipe Relining? Create feedback down below. We will be delighted to find out your suggestions about this blog entry. In hopes that you visit us again soon. You should set aside a second to promote this entry if you appreciated it. Thank-you for taking the time to read it.

Protect your property; contact now. Report this page